Laser Bonding – Thermark and Cermark Process

Thermark (or Cerdmark) when used with laser technologies allows permanent and indelible marks on many materials, including all non-coated metals and some coated metals, glass, marble, ceramics and a few plastics.

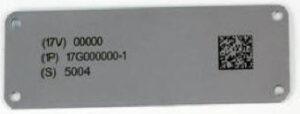

Marks using the Thermark or Cermark technique are non-intrusive and therefore does not harm the structural integrity of the material making this a perfect marking solution for aerospace, military and governmental industries to identify aircraft parts and all other parts, especially for UID.

The Thermark or Cermark process is also widely used for marking medical devices since this process always survives passivation, autoclave any salt spray tests.

Thermark material is similar to Cermark material and will work the exact same way. Thermark is grey and is easier to apply then Cermark and Thermark wipes off easier – That is why we prefer using Thermark.

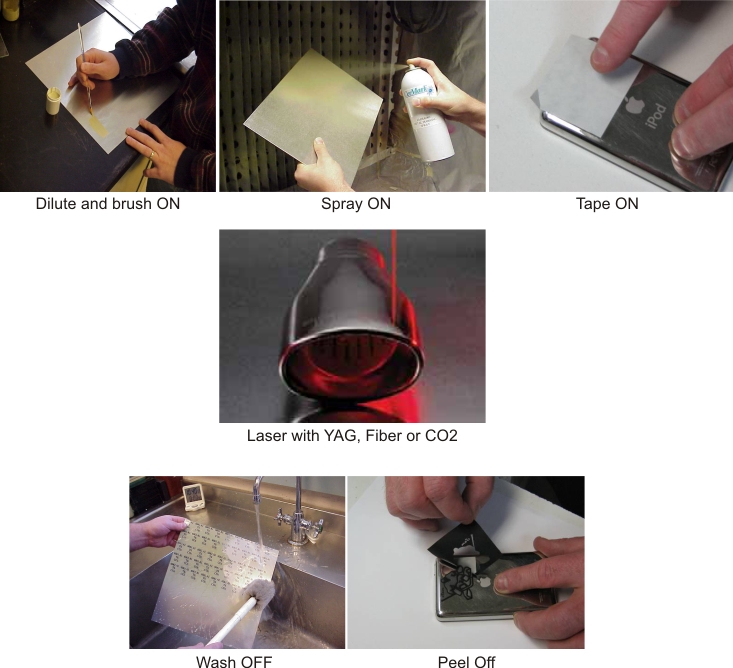

This graphic shows the entire process whether you choose – spray, tape or paste

Photo shows Thermark tape. Available in 1″ and 2″ and 3″ wide rolls. Rolls are 50′ long

For ordering Thermark tape click here and scroll down to the bottom

Photo shows Thermark spray LMM14 and the different sizes of paste.

For ordering Thermark spray or paste click here and scroll down to the bottom

Note between Thermark LMM14 spray and Cermark 6000 spray –

Thermark is a thinner solution and our experience is more reilable out of the can because it tends NOT to clog the spray nozzle. Cermark 6000 is clumpier and and tend to clog the spray nozzle unless you hodl the can unside down and spray until you are spraying only air out of the nozzle. This can be wasteful.

Also – Thermark is easier to wipe off then the Cermark – after the laser process.

Note about the Thermark tape –

Only one laser method in the world will mark anodized aluminum without ablating or damaging an anodized coating. Thermark tape can be applied on top of the anodized aluminum, then lasered. The resulting permanent mark does not damage the coating thereby keeping the full protection of the anodize.

Important Note: This tape is only available from TherMark and TherMark authorized distributors. It is a different product than the LMM6018 (non-LF) tape sold by Ferro and their distributors. TherMark discontinued the old thicker tape with the release of this new and improved product. If you used that product without success in the past, we urge you to give this product a try.

Photo shows Thermark tape process on top of clear anodized aluminum and therefore keepng the anodized layer in tact and protecting the aluminum underneath

Laser Bonding Process

The laser bonding process is non-intrusive to the material, as shown. The heat from the laser will heat the metal substrate below as well as the Thermark or Cerdec material and bond the material ON TOP of the substrate. This is NOT an engraving process

Some Examples:

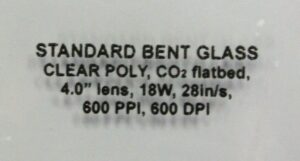

Glass

Glass

Aluminum

Steel – UID steel tag shown

Using TherMark and CerMark along with your CO2 or YAG or Fiber laser marking system — will result in high image quality, high-contrasting, permanent images.

TherMark or CerMark does not wear off and is not susceptible to corrosion. TherMark and CerMark allows the marking of such material as bare glass, bare aluminum, nylon with dark, easy to read images.