What Happens is Really Quite Simple

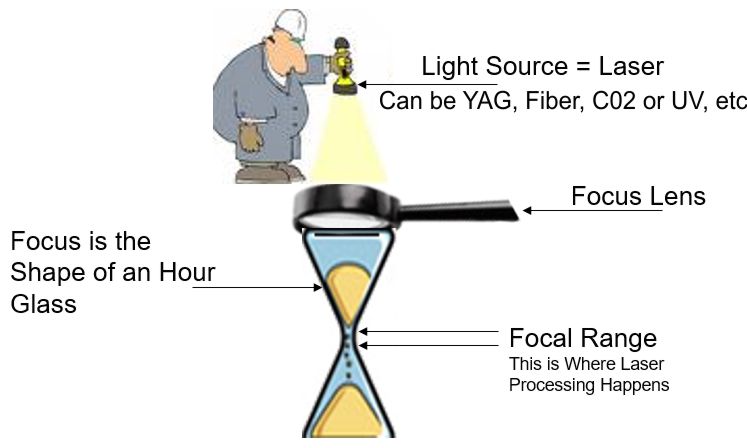

- A laser is simply a source of light. In this case, we use a flashlight as an analogy

- The light can be one of many different wavelengths – Fiber, C02, Green, UV, etc

- Material determines which laser is best as laser energy will “absorb into” or “bounce off”

- Laser light can be delivered many ways such as flatbed, galvanometer (galvo) or fixed head

The laser beam is delivered primarily using 3 methods

Galvanometer

- Marking

- Annealing Steel

- Deep Engraving Metal (fiber)

- Thin Material Cutting

Flatbed (XY Plotter)

- Marking

- Annealing (fiber)

- Engraving

- Cutting up to 1″

Fixed Head

- Cutting

- Welding

VERY General Overview of Differences

Galvanometer

- Speed

- Vectoring (hotter beam)

- Typically greater focus range

Flatbed (XY Plotter)

- Batch process (start and forget)

- Open Architecture (use any design software

- Larger, continuous process area

- Better for cutting compared to galvo

Fixed Head

- Parts translate using XY table

- Clean thin metal cutting

- Gas jet nozzle

- No alignment issues