Laserable Plastics

Matrix Magic!

Laserable Plastics – Examples: Trolase and Rowmark

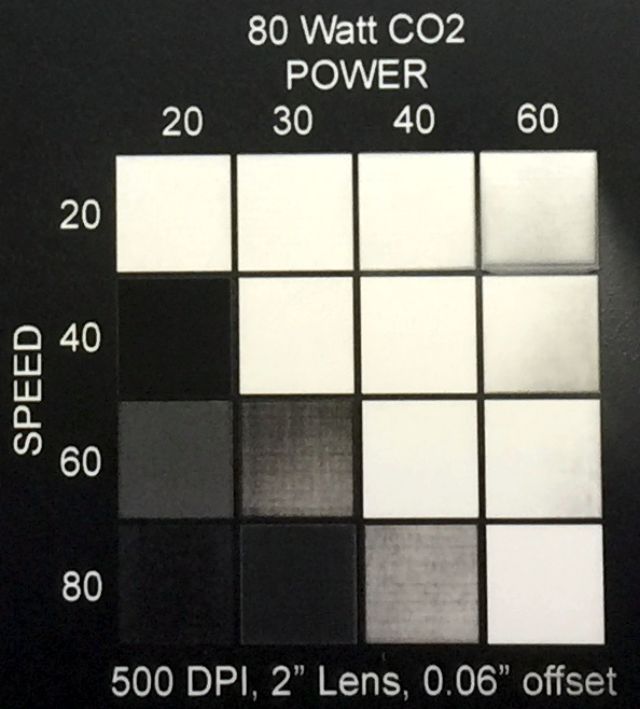

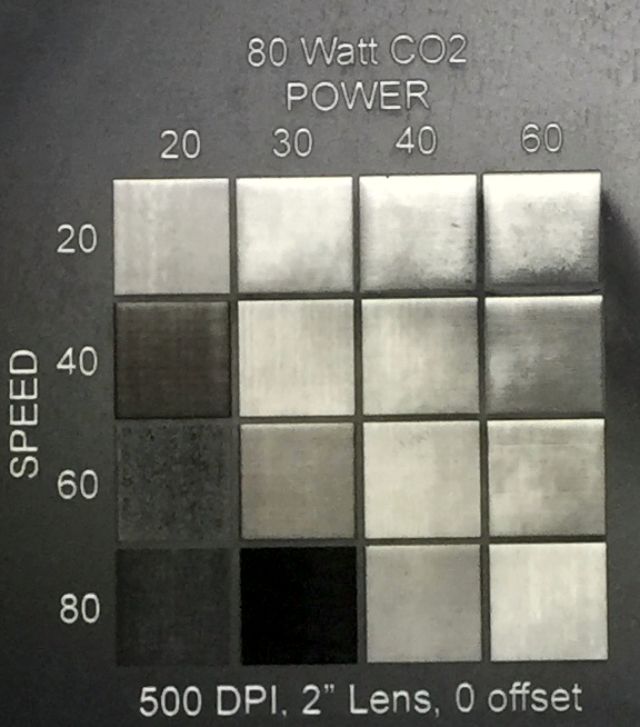

Below is a sample of Black/White Trolase plastic and ten matrices revealing a range of laser settings

Simply choose the desired box and set the laser settings as per the matrix settings and print the appropriate DPI

(see below for a list of constants and variables to create your own matrix)

The only difference in the two side by side photos (below) is a .06″ defocus

A matrix program is a great tool to determine best laser settings for any material. Each matrix below contains 16 boxes. Each box represents a snap shot of different laser power and speed settings shown by the numbers to the left and top of each matrix. Below is a list explaining constants and variables.

Constants:

- Trotec 80 watt Speedy 300

- Air assist flow very low

- 2″ lens

- Bottom up engraving

- Row 1 – directly in focus

- Row 2 – .060″ defocus

Variables:

- DPI (per matrix) left to right – 250, 333, 500, 600 and 1000

- Power ranges from 20% up to 60%

- Speed ranges from 20% up to 80%